Metal Building Engineered Structural Repairs

Column, I-beam and Steel Repair Services

Metal building structural repairs, including columns, I-beams, and steel components, play a pivotal role in maintaining the integrity and safety of industrial and commercial structures. As a metal building and steel repair company, Metalguard provides custom engineered services and innovative solutions for pre-engineered metal buildings.

Steel components, forming the backbone of many metal structures, are subject to wear and tear over time, necessitating repairs to prevent further deterioration. Our skilled team employs advanced techniques such as welding, reinforcement, and material replacement to reinforce and revitalize these crucial structural elements.

Our teams engineered structural repairs not only fix existing issues but also to enhance the overall resilience and longevity of the structure, ensuring years of productive use.

Column and I-beam Repairs

Our structural services start with a comprehensive assessment of your facility. For column repairs, we assess the extent of corrosion, damage, or other structural issues, and implement targeted solutions to restore stability. Steel components, forming the backbone of many metal structures, are subject to wear and tear over time, necessitating repairs to prevent further deterioration

Welding a replacement piece of steel onto a column.

A rusted out I-beam that has and gone through replacement.

Repairing Damaged I-beams

Due to a tropical storm, a warehouse roof collapsed due to the weight of the water. Fortunately, it landed on a stack of materials.

The first step we took was to shore the I-beam to prevent further damage and to be able to clear the area. After the materials were cleared, we found that the tilt-up wall had bowed out during the event.The first action required was to install stiff-backs to draw the wall back to be in the plane.

At completion, the wall had been straightened, and the I-beam was supported with a channel to support the I-beam.

Overhead Door frame / Upright C-Channel Repair

Before: This overhead door section was damaged, including the wall panel, trim, and the C-channel upright. We repaired the overhead door frame. The bollard was also damaged.

Experts In Repairing Metal Building Structural Damage

Engineered Structural Repairs - Our Process

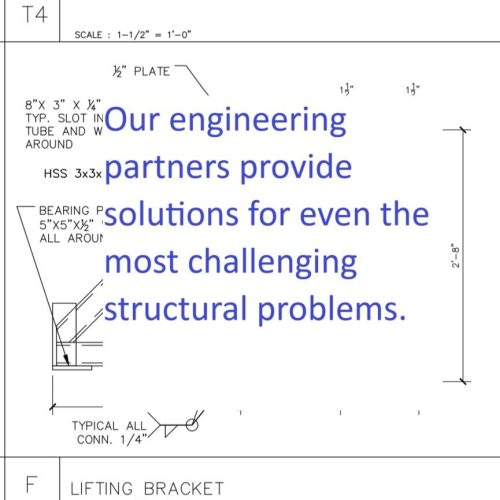

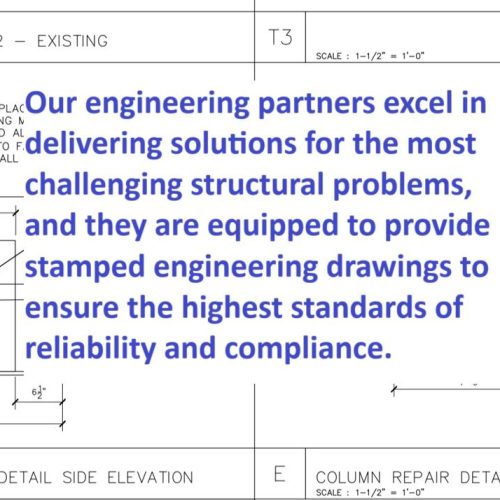

We repair a lot of damaged columns in industrial metal buildings. We work with a qualified licensed engineer partner. We have extensive experience repairing steel supports and developing custom solutions for metal buildings.

Tilt Wall Repair for Collapsed Roof

These pictures show where a roof was overwhelmed by rain from a tropical storm.The roof actually collapsed onto a pile of sheet rock. The tilt-wall bowed out and the beam broke free from the cement wall leaving a hole. First, we shored up the Large I beam. Then we installed bolt through welded “stiff-backs” which straightened out the wall. We then lifted the beam back into place. Then 2 welded channels were installed by bolting them through the wall. It was an unusual event that caused the problem that required innovative repairs to the wall.